The medical device industry is experiencing unprecedented growth, fueled by advancements in diagnostics, implantable technologies, and drug delivery systems. At the core of this innovation lies medical plastic injection molding - a precision manufacturing process that produces components with micron-level accuracy while adhering to stringent regulatory standards like ISO 13485 and FDA 21 CFR Part 820.

According to recent market reports from Grand View Research, the global medical injection molding market is projected to surpass $33 billion by 2030 and it is projected to grow at a CAGR of 5.8% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is primarily driven by the escalating demand for high-quality and precision-molded components in the healthcare industry.

For OEMs, procurement teams, and R&D engineers, partnering with top medical plastic injection molding companies ensures compliance, reduces risks, and accelerates time-to-market. These firms excel in cleanroom production, biocompatible materials, and end-to-end services, from design for manufacturability (DFM) to process validation (IQ/OQ/PQ). This guide analyzes the leading medical plastic injection molding companies, their specialties, and key selection criteria, drawing from industry sources like Plastics News, Verified Market Research, and company data.

Why Partner with Leading Medical Plastic Injection Molding Companies?

Medical plastic injection molding companies must navigate a complex landscape of regulatory requirements, material science, and precision engineering. Unlike general plastics manufacturers, these specialists deliver:

• Regulatory Mastery: Compliance with ISO 13485, FDA regulations, EU MDR, and MedAccred for seamless market entry and audit success.

• Ultra-Precision Capabilities: Tolerances as tight as ±0.0005 inches (12.7 microns) for micro-molded parts in IVD cartridges, microfluidic chips, and implantables.

• Material Innovation: Expertise in biocompatible polymers like PEEK, polycarbonate (PC), polypropylene (PP), ABS, and liquid silicone rubber (LSR), with testing for extractables/leachables and biocompatibility (ISO 10993).

• Scalability and Vertical Integration: From prototyping to high-volume production, including in-house tooling, assembly, ultrasonic welding, and sterile packaging.

• Global Resilience: Multi-site operations across the US, Europe, and Asia to mitigate supply chain disruptions, as seen post-pandemic.

• Sustainability Focus: Increasing use of recyclable resins and energy-efficient processes, aligned with EcoVadis and ISCC PLUS standards.

With applications spanning orthopedics, diagnostics, and drug delivery, these companies help OEMs address challenges like miniaturization (sub-millimeter features) and digital integration (Industry 4.0 sensors for real-time monitoring). Partnering early in the design phase can cut development time by up to 30% and ensure zero-defect production.

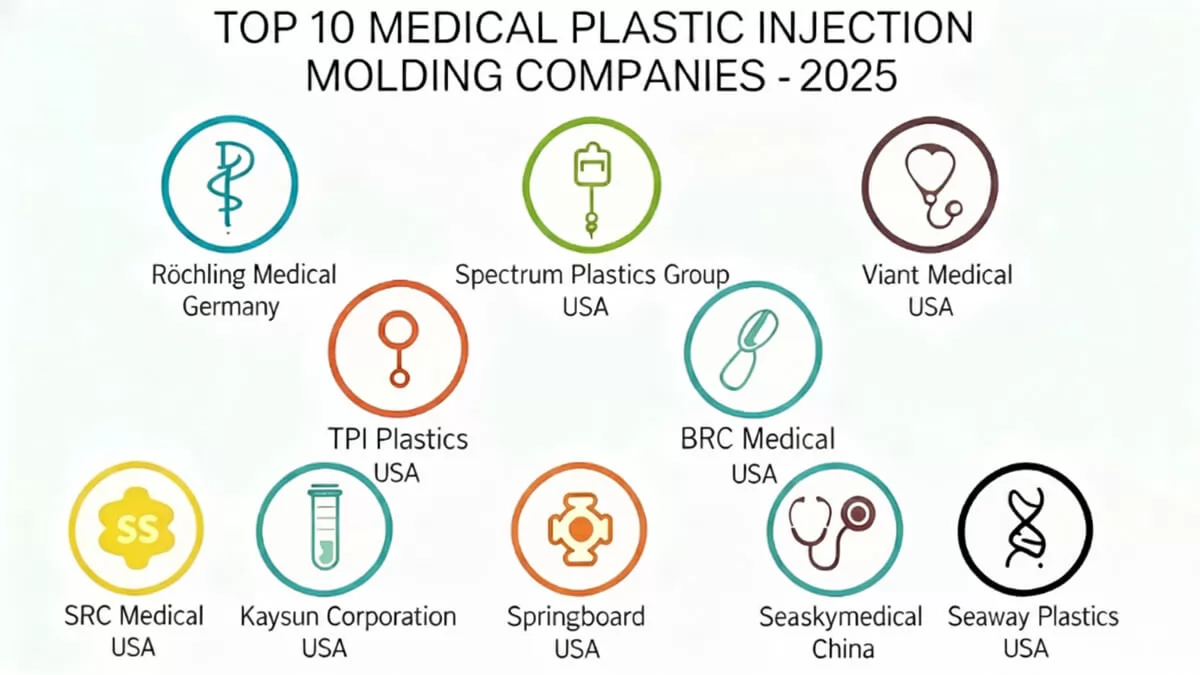

Top 10 Medical Plastic Injection Molding Companies in 2025

Based on market presence, certifications, facilities, client portfolios, and technological capabilities, here are the leading medical plastic injection molding companies. This curated list prioritizes firms with proven expertise in high-precision, regulated manufacturing.

1. Röchling Medical

• Description: A family-owned powerhouse with over 75 years in plastics, Röchling Medical specializes in pharmaceutical packaging, drug delivery systems, and diagnostic consumables. Their cleanroom operations (ISO Class 7/8) support micro-molding and automated assembly for high-volume OEM products. Key strengths include material innovation (e.g., bioabsorbable polymers) and sustainability certifications like EcoVadis and ISCC PLUS. They serve major pharma giants like Novo Nordisk, with capabilities for 1-micron micro-features on PEEK components.

• Headquarters: Neuhaus am Rennweg, Germany

2. Spectrum Plastics Group

• Description: Acquired by DuPont, Spectrum offers 61 years of expertise in implantables, bioresorbables, and catheter technologies. Their vertically integrated services include extrusion, medical balloons, laser processing, and quick-turn prototyping in ISO Class 7/8 cleanrooms. With over 300 injection machines (15-3,000 tons), they emphasize scientific molding for tolerances of ±0.001 inches. Spectrum serves 22 of the top 26 medical OEMs, excelling in structural heart and surgical robotics applications.

• Headquarters: Alpharetta, GA, USA

3. TPI Plastics (Trademark Plastics Inc.)

• Description: Founded in 1989, TPI is a vertically integrated leader in custom medical components for IVD supplies and microfluidic chips. Their 100,000 sq. ft. facility features 51 machines (6-610 tons), ISO Class 8 cleanrooms, and advanced metrology like ZEISS CT scanners for non-destructive inspection. Achieving tolerances of ±0.0005 inches via RJG-certified scientific molding, TPI provides full IQ/OQ/PQ validation and serves 8 of the top 30 global medical OEMs. Ideal for diagnostics with dual US/China operations for supply chain security.

• Headquarters: Riverside, CA, USA

4. Viant Medical

• Description: Viant is a single-source partner for orthopedics, surgical tech, and drug delivery, with expertise in overmolding, extrusions, and complex assemblies. Their 25 facilities include ISO Class 7/8 cleanrooms and MDSAP-certified operations. Strong in hybrid metal-plastic components for auto-injectors and wearables, Viant supports prototyping to scale-up, with a focus on speed-to-market and EU MDR compliance.

• Headquarters: Orchard Park, NY, USA

5. BMP Medical

• Description: With 45+ years of experience, BMP specializes in precision IVD components and injection blow molding in an 80,000 sq. ft. facility with ISO Class 8 cleanrooms. ISO 13485:2016 and FDA-registered, they offer agile co-development, material selection, and scalable production for low-to-medium volumes. BMP excels in disposable diagnostics and lab consumables, with robust eQMS for traceability.

• Headquarters: Sterling, MA, USA

6. Seaskymedical

• Description: An ISO 13485-certified specialist in cleanroom molding (ISO Class 8), Seaskymedical provides one-stop solutions for micro-injection molding (parts 0.1-0.5g, walls 0.2mm thin), insert/overmolding, and assembly. Handling biocompatible materials for IVD and pharma devices, they offer cost-effective, high-cleanliness production with FDA/CE compliance. Strong in global logistics for US/EU markets.

• Headquarters: Shenzhen, China

7. Springboard Manufacturing

• Description: ISO 13485-certified, Springboard offers full-service tooling, cleanroom molding, and assembly in 150,000 sq. ft. facilities. Specialties include micro-molding, ultrasonic bonding, and Lean principles for high-volume FDA-approved devices. Ideal for startups and OEMs needing rapid prototyping and electronics integration.

• Headquarters: Rancho Cordova, CA, USA

8. SRC Medical

• Description: Established in 1972, this family-owned firm specializes in delivery devices like applicators and dropper assemblies in an 80,000+ sq. ft. facility with 25 machines. ISO 13485, FDA, and CE-compliant, SRC emphasizes robotic assembly and quality assurance for pharma and medical sectors.

• Headquarters: Hanover, MA, USA

9. Kaysun Corporation

• Description: Renowned for complex custom molding, Kaysun holds MedAccred, ISO 13485, IATF, and ITAR accreditations. They support IQ/OQ/PQ validations, scientific molding, and overmolding for life-saving products, with a sustainability focus (diverting millions of pounds of waste). Partners with major OEMs in surgical instruments and implantables.

• Headquarters: Manitowoc, WI, USA

10. Seaway Plastics

• Description: ISO 13485-certified with 35,000+ sq. ft. of ISO Class 7/8 cleanrooms, Seaway excels in low-to-mid volume projects using 700+ thermoplastics and LSR. Services include DFM, cleanroom assembly, welding, and shielding for medical, aerospace, and defense applications.

• Headquarters: Port Richey, FL, USA

Quick Comparison Table of Medical Plastic Injection Molding Companies

|

Company |

Headquarters (Key Locations) |

Key Specialties |

Certifications |

Cleanroom Class |

Tolerance Capability |

|

Röchling Medical |

Germany (US, China) |

Packaging, drug delivery, diagnostics |

ISO 13485, EcoVadis, ISCC PLUS |

ISO 7/8 |

±0.001 inches |

|

Spectrum Plastics Group |

GA, USA (Global) |

Implantables, catheters, balloons |

ISO 13485, MDSAP, AS9100 |

ISO 7/8 |

±0.001 inches |

|

TPI Plastics |

CA, USA (US, China) |

IVD supplies, microfluidics |

ISO 13485, MedAccred, FDA |

ISO 8 |

±0.0005 inches |

|

Viant Medical |

NY, USA (Global) |

Orthopedics, drug delivery, overmolding |

ISO 13485, MDSAP, cGMP |

ISO 7/8 |

±0.001 inches |

|

BMP Medical |

MA, USA |

IVD components, blow molding |

ISO 13485, FDA |

ISO 8 |

±0.002 inches |

|

Seaskymedical |

China (Global) |

Micro-molding, insert/overmolding |

ISO 13485, FDA, CE |

ISO 8 |

±0.001 inches |

|

Springboard Manufacturing |

CA, USA (NE, USA) |

Cleanroom assembly, micro-molding |

ISO 13485, UL |

ISO 8 |

±0.002 inches |

|

SRC Medical |

MA, USA |

Delivery devices, applicators |

ISO 13485, FDA, CE |

ISO 8 |

±0.0015 inches |

|

Kaysun Corporation |

WI, USA |

Complex molding, validations |

MedAccred, ISO 13485 |

ISO 8 |

±0.0005 inches |

|

Seaway Plastics |

FL, USA (US sites) |

LSR, cleanroom molding |

ISO 13485, NADCAP |

ISO 7/8 |

±0.001 inches |

Deep Dive: Key Expertise Areas in Medical Plastic Injection Molding

Top medical plastic injection molding companies shine in specialized domains like micro-molding and material science.

• Micro-Molding Mastery: Essential for sub-millimeter features in IVD and implantables. TPI and Seaskymedical achieve parts under 0.5g with 0.2mm walls, using wire-EDM tooling and cavity pressure control for repeatability. Spectrum excels in microfluidic chips, while Viant focuses on orthopedic micro-components.

• Material and Process Innovation: Common resins include PEEK for implants (high strength) and PC for optics (clarity). Companies like Röchling pioneer bioresorbable polymers, while Kaysun uses scientific molding for uniform walls and gate design. Trends include AI-optimized cycles and hybrid 3D printing for tooling.

• Case Studies: TPI reduced a diagnostic OEM's development time by 30% via DFM and CT scanning. Röchling supplied zero-defect insulin pens for 24 months. Spectrum's bioresorbable stents hit market in 6 weeks.

How to Choose a Medical Plastic Injection Molding Partner

1. Assess Medical Experience: Review case studies in your niche (e.g., IVD for TPI, drug delivery for SRC).

2. Verify Certifications: Prioritize ISO 13485, MedAccred, and cleanroom classes; request audit reports.

3. Evaluate Facilities: Check in-house tooling, metrology (CMM/CT scanners), and global sites for resilience.

4. Test Scalability: Ensure capacity for prototyping to high-volume, with dual-sourcing options.

5. Demand Innovation: Seek DFM, rapid prototyping, and material validation expertise.

6. Review Quality Systems: Require IQ/OQ/PQ, traceability, and biocompatibility testing.

7. Foster Collaboration: Choose partners like BMP for co-development or Kaysun for engineering support.

8. Conduct Due Diligence: Site visits, references, and financial checks; start with a pilot project.

Conclusion

In 2025, top medical plastic injection molding companies like Röchling, Spectrum, and TPI are pivotal to healthcare advancements, offering precision, compliance, and innovation for life-saving devices. For high-precision IVD needs, TPI's vertical integration and cleanroom expertise stand out - contact trademarkplastics.com or (951) 231-1480 to explore partnerships. Engage early to ensure compliant, efficient solutions that propel your products to market faster.