• Specialized micro-capable presses and shot-size control.

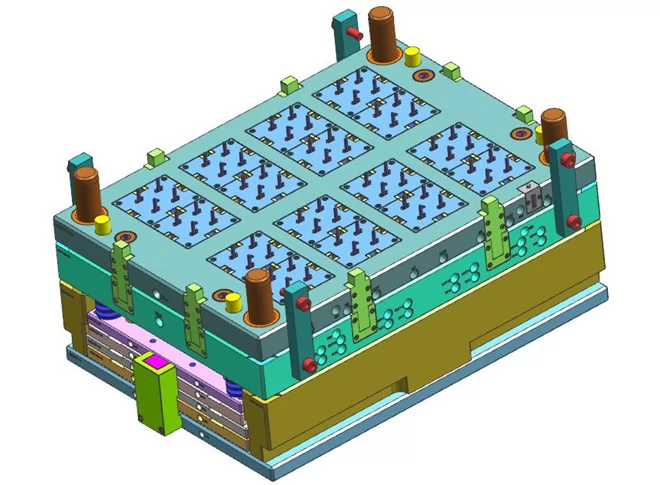

• Extremely fine cavities and gates machined by EDM or micro-milling.

• Tight mold temperature control and advanced cooling strategies.

• In-line metrology and scientific molding practices for repeatability.

• Extreme precision and repeatability. Micro molding routinely supports the tolerances required by IVD cartridges, microfluidics, micro-connectors, and optical components.

• Small, dense geometries. Micro gears, channels, valves, and acoustic paths are possible in high volumes without multi-piece assembly.

• Material & biocompatibility options. Medical-grade thermoplastics and specialty resins compatible with sterilization and low-extractables are available for micro molding.

• Compact tooling and faster iterations. Smaller molds can shorten tooling lead times and reduce cost for early development and low-to-medium production volumes.

• Validated, regulated processes. Micro molding providers that operate under ISO 13485 and offer IQ/OQ/PQ documentation simplify regulatory submission and manufacturing transfer.

| Characteristic | Typical Range / Example |

| Dimensional tolerances | Sub-0.01 mm (≤ 10 µm) common; specific features achievable to ~0.0127 mm (0.0005") or better in validated setups |

| Minimum feature size | Features and wall sections < 0.5 mm commonly produced; channels and radii in the single-digit micron range possible for select designs |

| Shot weight | Fractions of a gram to a few grams — precise shot control required |

| Process controls | Scientific molding, cavity pressure/temperature monitoring, in-line metrology, and traceable lot control |

| Tooling technology | EDM, wire-EDM, micro-milling, and diamond-finish EDM for optical surfaces |

• Polycarbonate (PC) and PC blends - good optical properties and dimensional stability for lenses and rigid components.

• PEEK and PPSU - for high-temperature and sterilizable components.

• Medical - grade polyurethanes and elastomers - for flexible micro-features, seals, and over-molded elements.

• Specialty low - extractable resins - critical for reagent - contacting IVD parts.

1. Simplify critical dimensions. Minimize the number of micron-critical features. When possible, design features to be tolerant of small dimensional shifts.

2. Uniform wall thickness. Aim for consistent wall sections; very thin, abrupt transitions cause filling issues and local stress. Use ribs very sparingly — micro ribs often cause flow irregularities.

3. Gate and vent design. Use tuned gate locations and appropriately sized vents to prevent air traps. Micro vents or flow channels in the mold are often necessary.

4. Draft and parting lines. Maintain realistic draft angles - even micro parts need draft to release cleanly. Consider micro-texture feasibility and its effect on functional surfaces.

5. Tolerance stack planning. Build realistic tolerance stacks and involve your molder early. Simulation at micro scale is useful but not definitive; plan for rapid mold trials and prototype iterations.

6. Feature orientation. Wherever possible, orient critical features to take advantage of flow and consistent cooling. For optical or sealing surfaces, consider insert molding or post-process operations if necessary.

7. Avoid isolated thin sections. Isolated thin sections can cool too fast or slow, causing sink, voids, or dimensional drift.

• Tooling: wire-EDM, micro-EDM, micro-milling, and precision polishing are standard. Tool steel selection and thermal control of cavities are essential.

• Mold temperature control: tight and uniform temperature control reduces shrinkage variance and improves dimensional repeatability.

• Shot control and feed: micro shot sizes demand extremely accurate feed systems and back-pressure control to ensure consistent melt conditions.

• Scientific molding: detailed process maps, cavity pressure monitoring, and controlled injection speed/hold profiles are used to lock-in repeatable cycles.

• In-line metrology: optical inspection systems, automated vision, and periodic CT/X-ray checks are used depending on feature criticality.

• Validation: IQ/OQ/PQ protocols are standard for medical micro molding to demonstrate process capability and repeatability.

• ISO 13485 alignment for medical device contract manufacturing.

• Process validation: documented IQ/OQ/PQ and documented process capability studies.

• Traceability: lot and material traceability, material certificates, and incoming inspection records.

• Biocompatibility & extractables testing: test parts molded using production tooling and processes.

• Cleanroom/white - room production: necessary for many IVD and implantable products; consider certified clean zones for assembly and packaging.

• First article and run records: first article inspection (FAI) typically includes dimensional reports, CT/X-ray or micrographs, and functional test evidence.

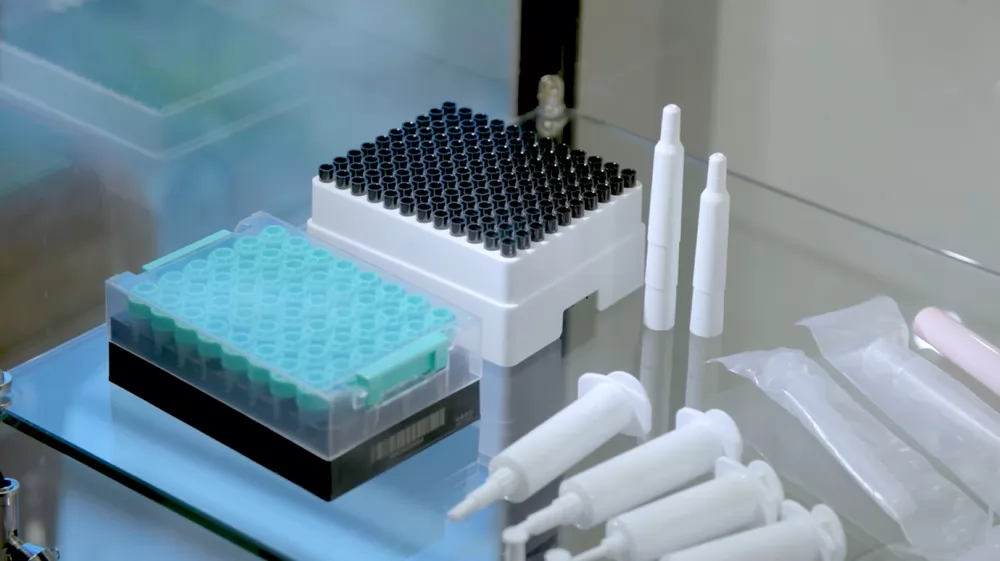

• IVD cartridges and microfluidic chips: micro channels, valve seats, and reagent wells with precise volumes and surface finishes.

• Implantable device features: miniature polymer features for controlled drug delivery, anchors, or articulating micro-components.

• Hearing aids and wearables: micro housings, acoustic paths, and tiny connectors.

• Micro optics and lenses: micro-molded optical elements requiring excellent surface finish and form control.

1. Demonstrated micro molding experience with medical parts - ask for sample parts and case studies.

2. Quality certifications - ISO 13485 and documented medical production systems.

3. In-house tooling & metrology - EDM, micro - mills, CT/X-ray, and high-precision coordinate measuring systems (CMM or optical metrology).

4. Cleanroom capability for assembly and packaging.

5. Process validation & documentation - IQ/OQ/PQ, lot traceability, and documented CAPA procedures.

6. Willingness to run material validation at micro shot sizes and to perform biocompatibility/extractables testing on molded parts.

7. Rapid prototyping and short-run tooling options for iterative development.

1. Engage a micro molder early - involve their tooling and process engineers during concept design.

2. Prototype and iterate quickly - expect several mold trials to dial in tolerances and material behavior.

3. Validate on production process - run biocompatibility and extractables on production-molded parts.

4. Request documentation - IQ/OQ/PQ plans, metrology reports, and capability studies before production release.

5. Use a downloadable checklist (DFM + tolerances + validation steps) to guide internal reviews.