TPI provides comprehensive tooling solutions that span the entire mold lifecycle—from design and engineering to manufacturing, validation, and ongoing maintenance. With mold production carried out by our overseas R&D center, we combine global resources with local expertise to deliver high-quality, cost-efficient solutions.

Mold R&D & Manufacturing Center

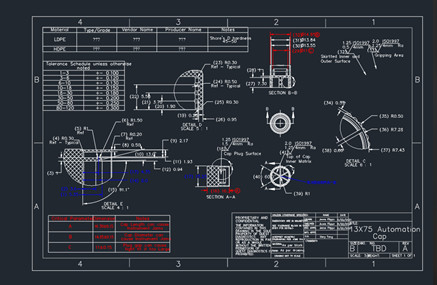

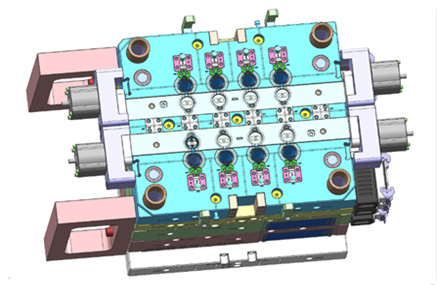

Our overseas Mold R&D Center specializes in high-cavity, high-efficiency, and high-precision molds. By integrating IoT technologies, advanced software, and modern equipment, we deliver customized mold solutions that accelerate time-to-market and improve product reliability. With decades of experience and thousands of molds delivered, we support a wide range of industries with intelligent manufacturing capabilities.

Tooling Maintenance at TPI

At our U.S. facility, TPI provides in-house mold maintenance and repair services to maximize tool life and ensure consistent part quality. From preventive care to complex refurbishments, our dedicated team safeguards your tooling investment and minimizes downtime.

Our robust production capabilities enable us to comprehensively meet diverse client requirements.

| Class 8 Cleanroom A | Class 8 Cleanroom B | White Room A | White Room B | Controlled Room | TPI Total | |

|---|---|---|---|---|---|---|

| Below 60 Ton | 1 | 1 | 2 | 4 | ||

| 60-90 ton | 4 | 1 | 5 | |||

| 110-120 ton | 6 | • | 6 | |||

| 150 – 180 ton | 1 | 1 | 4 | 1 | 7 | |

| 200 ton | 2 | 10 | 5 | 17 | ||

| 250 ton | 1 | 3 | 4 | |||

| 300 ton | 5 | 5 | ||||

| 390-400 ton | 1 | 1 | ||||

| 450-610 ton | 2 | 2 | ||||

| Total | 14 | 13 | 19 | 3 | 2 | 51 |

We streamline your order process—from online quotes to high-quality mold making and production-ready plastic parts. Our expert team and state-of-the-art machinery guarantee efficiency and timely delivery.

We start with understanding your product requirements, materials, and end-use applications to define the best manufacturing approach.

Our engineering team works closely with you to optimize part design for manufacturability, efficiency, and cost-effectiveness.

Rapid prototyping ensures design validation and functional testing before tool investment.

We build high-precision, long-life injection molds tailored to your product specifications and production volume.

Comprehensive validation ensures compliance with regulatory standards and guarantees consistent, high-quality parts.

Once validated, production begins in our ISO 13485 certified facility with scalable capacity and strict quality control.

A Vertically Integrated Contract Manufacturer Providing Engineering Solutions to the Healthcare Industry

Bridge the gap between concept and production. We deliver high-precision injection molded prototypes in as fast as 5 days using aluminum and steel tooling. ISO 9001 & 13485 Certified.

Precision Mold Design for Manufacturability and Efficiency

Integrated Solutions Beyond Injection Molding