A Vertically Integrated Contract Manufacturer Providing Engineering Solutions to the Healthcare Industry

High-Precision Molding & Manufacturing Applications

Trademark is a global leader in the Healthcare space providing advance technologies to ensure your molding and assembly programs are successfully launched. We provide full support through the life cycle of new products connecting design, injection molding and assembly. As a vertically integrated provider, we guide your products from concept to commercialization, working with startups, OEM’s to accelerate innovation to meet the evolving needs of our customers. Development and manufacturing expertise proven by established and successful programs.

Comprehensive Manufacturing Solutions

For Medical Device & Diagnostic Industries

Engineering

Experienced design, Manufacturing and process engineers are engaged throughout every customer project. This attention to detail ensures faster development times, fewer issues, and projects that are optimized for manufacturing.

• Project engineers dedicated to support day to day operations, production line optimization, automation, secondary operations, fixture designs, and manufacturing optimization.

• Processing engineers utilize Scientific Molding principles to maximize yields, minimize scrap, and troubleshoot molding parameters that may impact product quality.

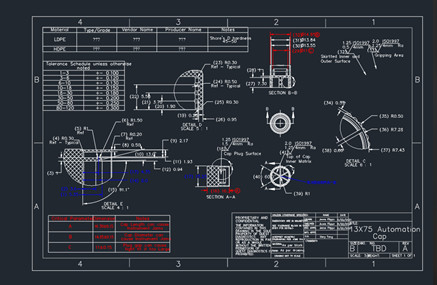

• Tool Design Engineers skilled to Design for Manufacturability, Plastics Part Design, Mold Design, and managing all aspects of New Product Introduction.

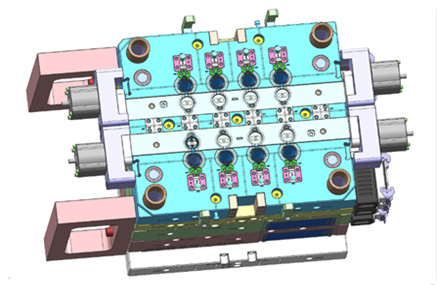

Tooling : Fabrication

Our state of the art, fully staffed and equipped toolroom is dedicated to support your injection molding projects throughout the entire lifecycle: design consultation, tool build, rapid repairs and modification, and perform regularly scheduled maintenance to minimize downtime. Trademark tooling solutions will provide your organization with the lowest possible total cost of ownership for the lifetime of the mold.

• In-house, outsourced domestic and overseas toolmaking capabilities to address your quality, budgetary and lead time objectives.

• Fully staffed and equipped toolroom.

• Equipment Includes:

EDM's (Electric Discharge Machines) and auxiliary equipment

CNC Vertical Machining Centers

Grinding Lathe and Milling Machines

Quality Assurance

Trademark Quality Assurance is integral to every client program, and involved from design through execution. We assist our clients by designing robust process window through design of experiments and validations, establishing process controls, and identifying reliable measurement methods. We pride ourselves on mitigating risk to continuous supply and helping your supply chain execute total cost initiatives such as supplier consolidation, inventory management, and lead time optimizations. To ensure continuity for every client all Trademark operational functions are manage through our IQMS enterprise resource planning systems that completely integrates quality into every aspect of our business.

• ISO13485 Certified to ensure strict procedural and documentation compliance with your industry regulations.

• Class 8 Controlled and audited cleanrooms to ensure cleanliness of molded parts.

• In-house visual and probe CMM equipment to perform detailed part inspections and first article reporting.

• Perform part validation inclusive of IQ, OQ & PQ.

Our robust production capabilities enable us to comprehensively meet diverse client requirements.

| Class 8 Cleanroom A | Class 8 Cleanroom B | White Room A | White Room B | Controlled Room | TPI Total | |

|---|---|---|---|---|---|---|

| Below 60 Ton | 1 | 1 | 2 | 4 | ||

| 60-90 ton | 4 | 1 | 5 | |||

| 110-120 ton | 6 | • | 6 | |||

| 150 – 180 ton | 1 | 1 | 4 | 1 | 7 | |

| 200 ton | 2 | 10 | 5 | 17 | ||

| 250 ton | 1 | 3 | 4 | |||

| 300 ton | 5 | 5 | ||||

| 390-400 ton | 1 | 1 | ||||

| 450-610 ton | 2 | 2 | ||||

| Total | 14 | 13 | 19 | 3 | 2 | 51 |

We streamline your order process—from online quotes to high-quality mold making and production-ready plastic parts. Our expert team and state-of-the-art machinery guarantee efficiency and timely delivery.

We start with understanding your product requirements, materials, and end-use applications to define the best manufacturing approach.

Our engineering team works closely with you to optimize part design for manufacturability, efficiency, and cost-effectiveness.

Rapid prototyping ensures design validation and functional testing before tool investment.

We build high-precision, long-life injection molds tailored to your product specifications and production volume.

Comprehensive validation ensures compliance with regulatory standards and guarantees consistent, high-quality parts.

Once validated, production begins in our ISO 13485 certified facility with scalable capacity and strict quality control.

Bridge the gap between concept and production. We deliver high-precision injection molded prototypes in as fast as 5 days using aluminum and steel tooling. ISO 9001 & 13485 Certified.

Precision Mold Design for Manufacturability and Efficiency

High-Precision Mold Design, Manufacturing, Lifecycle Support

Integrated Solutions Beyond Injection Molding