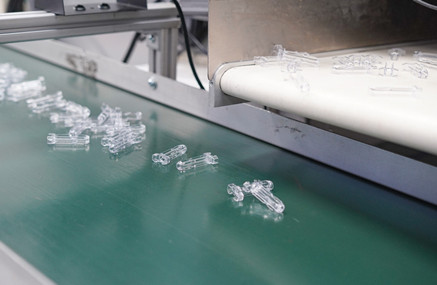

Injection-molded plastics protect and connect the world of electronics. Durable housings, connectors, and precision components enable safe, efficient, and high-performance devices across a wide range of applications.

A dedicated team of manufacturing experts managing every stage—from prototype to mass production—while keeping you informed throughout.

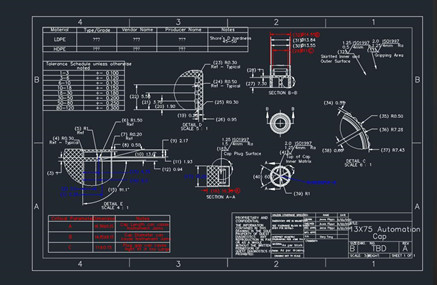

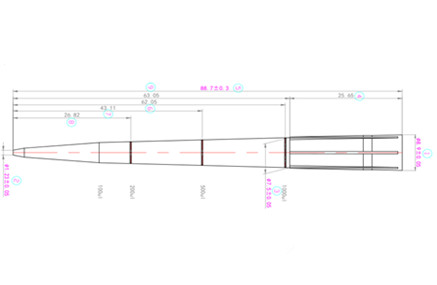

Create high-fidelity prototypes with production-grade materials to validate design, fit, and function early in the development process.

Test and refine functional prototypes to ensure performance requirements are met, enabling fast iterations and design improvements.

Assess your medical product's functionality, usability, and appearance, making adjustments to optimize production efficiency and cost.

Prepare your design for full-scale manufacturing with production-grade processes and rigorous quality management systems.

Transition seamlessly from validation to large-scale production of end-use medical components, ensuring consistency and regulatory compliance.

Leverage TPI's agile prototyping and streamlined processes to accelerate design validation and bring products to market faster.

Offering full turnkey solutions, TPI is your one-stop partner for excellence!

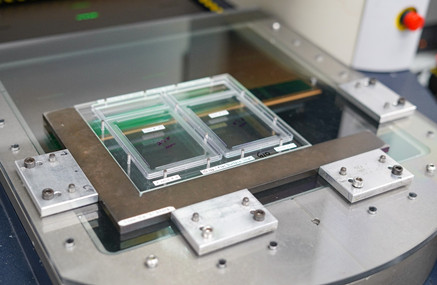

ISO Class 8 cleanrooms and controlled white rooms safeguard product quality with contamination-free production.

We provide global-standard quality at highly competitive pricing, helping you control costs without compromising performance.

With over 35 years in medical injection molding, TPI delivers trusted knowledge and reliable results for the world's leading brands.

Our vertically integrated systems and 24/7 production capacity ensure your products reach the market on time, every time.

Speed, quality, and technical expertise are built into our entire process. Partnering with us helps ensure your design is optimized, your development timeline is accelerated, and that you're supported from prototyping through end-use production.