Founded in 1989, Trademark Plastics, Inc. (TPI) is a U.S. based contract manufacturer specializing in custom plastic injection molding for the medical device, life science, and diagnostic industries.

With over 35 years of expertise, TPI serves a global customer base including 8 of the world’s top 30 medical device companies by delivering precision, speed, and reliability at every stage of the manufacturing process.

Partner with TPI and work with some of the industry's top experts. From concept to completion, we provide full turnkey solutions for excellence.

_1751965895_WNo_1168d1446.jpg)

▶ Custom plastic injection molding

▶ Scientific molding (RJG-certified)

▶ Mold design & validation (DFM, DOE, Moldflow)

▶ Tool fabrication, repair, and lifecycle maintenance

▶ Assembly, kitting, packaging

▶ IQ/OQ/PQ process validations

▶ Full traceability and batch documentation

▶ Location: Riverside, California, USA

▶ Total Area: 100,000 sq. ft.

▶ Cleanroom Manufacturing:

• 2x ISO Class 8 cleanrooms

• 2x controlled-environment white rooms

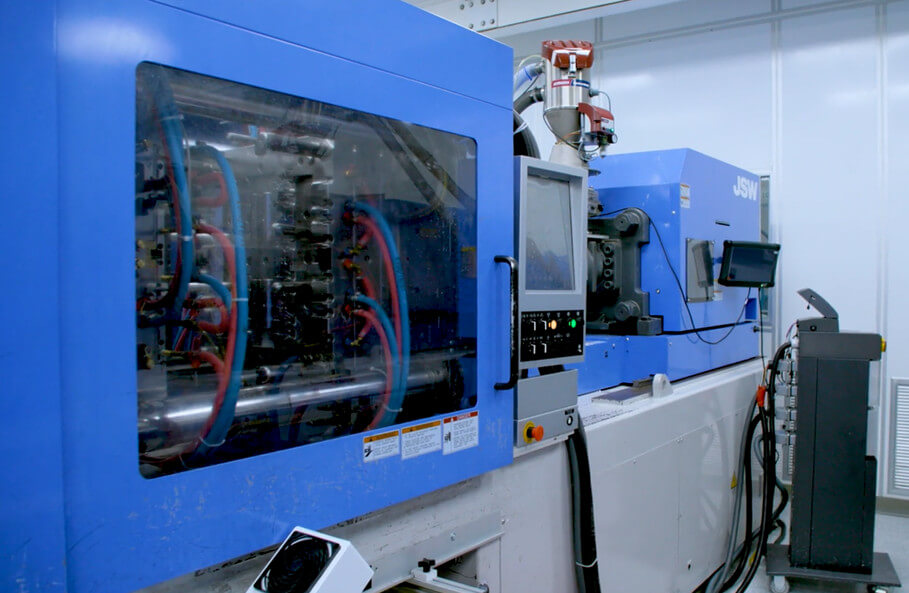

▶ Injection Molding Machines:

• 51 machines ranging from 6 to 610 tons

▶ Tool Room: In-house maintenance, repairs, and modifications

▶ Logistics: Integrated warehousing, receiving, packaging & distribution

▶ ERP System: IQMS fully integrated

▶ Precision Molding & Full-Service Capabilities

TPI provides complete, vertically integrated injection molding solutions - from early-stage DFM and prototyping to full-scale production, assembly, and packaging.

Engineering Expertise That Drives Results

Our multidisciplinary team includes certified engineers, RJG Master Molders, and Lean Six Sigma Black Belts - all focused on improving quality, reducing waste, and accelerating your product to market.

• Engineering Capabilities:

• Scientific molding development

• DOE and process window validation

• Custom fixtures and automation integration

• PFMEA, Control Plans, and risk mitigation

• SolidWorks, SmartTech, Beaumont & MIT-certified team

Quality Assurance & Metrology Excellence

At TPI, quality is embedded from design through delivery. Our systems meet the strictest global regulatory standards, and we invest heavily in in-process monitoring and precision inspection.

▶ Certifications & Compliance:

• ISO 13485 certified

• MedAccred accredited

• FDA-compliant practices 21 CFR Part 820

• Full traceability and lot control

• n-site QC lab with dimensional, visual, and functional testing

▶ Metrology & Validation Tools:

• ZEISS Metrotom 800 CT for x-ray level inspection

• 2x OGP SmartScope Flash w/ touch probe

• Digital height gage, bore gages, micrometers

• Moisture analyzer, force dial gages, durometers

• SPC-enabled data collection at the machine and lab level

Tooling That Maximizes Performance

Our tooling services ensure longevity, consistency, and precision throughout the lifecycle of your product.

▶ Capabilities:

• Early-stage consultation and DFM

• Moldflow analysis to reduce risk

• Domestic and international tool sourcing

• In-house repairs, retrofits, and optimization<

• Preventive maintenance programs

TPI specializes in custom injection molding for the medical device, life science, and diagnostics industries. We partner with leading OEMs worldwide—including 8 of the top 30 medical device companies—to deliver cleanroom-manufactured, validated components that meet the strictest regulatory requirements.

Yes. TPI provides end-to-end solutions, including design-for-manufacturing (DFM), prototyping, tooling, process validation (IQ/OQ/PQ), cleanroom molding, assembly, packaging, and distribution. Our vertically integrated approach ensures faster launch, reduced risks, and cost efficiency.

Quality is built into every step of our process. TPI is ISO 13485 certified, MedAccred accredited, and FDA 21 CFR Part 820 compliant. We use advanced metrology tools—including a ZEISS Metrotom 800 CT scanner for x-ray level inspection—and maintain full traceability with IQMS ERP and lot control.

We operate two ISO Class 8 cleanrooms and two controlled-environment white rooms, supporting the production of sterile and particle-sensitive components. All cleanroom operations follow strict quality protocols to ensure consistency and compliance with global medical standards.

Absolutely. With 51 molding machines (6–610 tons) and scalable operations, TPI can support everything from early-stage prototyping to 24/7 high-volume production. Our scientific molding expertise (RJG-certified) ensures repeatability and precision at any scale.

TPI offers complete tooling lifecycle support, including DFM consulting, Moldflow analysis, sourcing, in-house maintenance, and preventive programs. This ensures your molds deliver long-term reliability, reduced downtime, and optimal performance throughout production.

Every project is assigned a dedicated Program Manager who oversees milestones, communicates updates, and coordinates seamlessly between engineering, tooling, quality, and production teams. This structured approach ensures on-time launches and predictable results.